ABOUT BEMOULD

Bemould is a company dedicated to the research and development, production, and sales of injection molds, committed to providing customers with high-quality and efficient mold solutions.

Our products cover various types

of injection molds, including automotive parts injection molds, industrial parts injection molds, home appliance injection molds, etc., to meet the needs of different customers.

In addition, we also provide one-stop

services such as injection molding and plastic product testing, Help customers generate product efficiency and quality in advance .

1. 100g to 4000g brand new injection machines over 10 sets ;

2. Quality assurance : IATF 16949 , ERP+APS+MES system ;

3. 20,000 pcs/day production capacity , delivery time is guaranteed ;

4. Providing all-in-one plastic product services , no time and money waste.

Injection Molded For Various Industries

Bemould has been committed to injection molding for many years, and we firmly believe that providing good service and quality will enable us to go further.

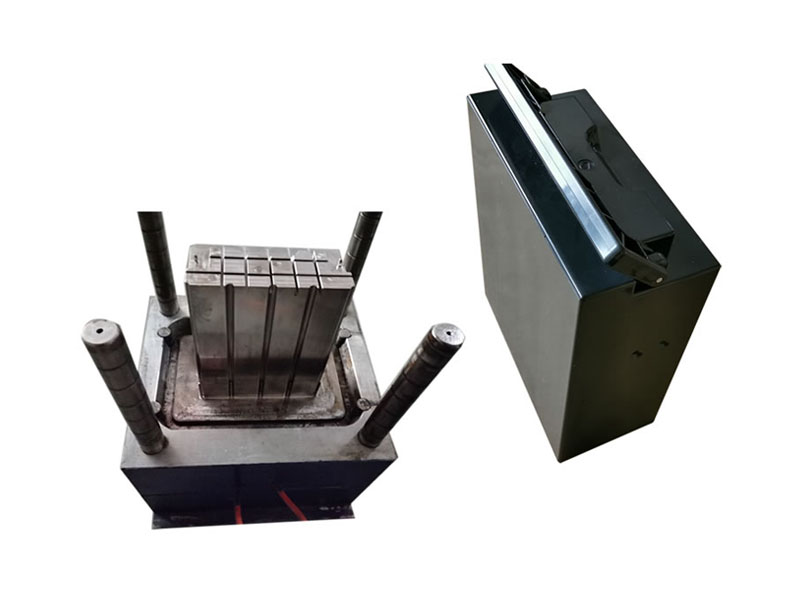

We serve customers in different industries. While manufacturing molds and supplying plastic products in bulk, our team also independently develops new products. Bemould focuses on market demand, opens up new

teams and production lines to support the development and production of new products . We have just passed the test and launched a new outdoor energy storage device - Portable Power Station. This is the preferred Portable Power

Station for family and friends camping during holidays. It is lightweight and has sufficient power supply, ensuring that you do not lack power during outdoor activities !

The perfect plastic shell of this product is independently designed, sampled, mold designed and manufactured, and finally tested by us. Our team has been able to excellently complete the entire product development, design,

and manufacturing process .

Welcome to consult us at [email protected]. Whether it's plastic product development and design, material selection of plastic products, or custom

injection molding, we have professional engineers to provide you with answers.

One-Stop Plastic Injection Molding Solution

Bemould : A first-class team, one-stop service, allowing customers to cooperate with us with peace of mind, providing you with guaranteed product quality, the shortest service cycle, no intermediate price difference,

and the most cost-effective product cost !

At the beginning of Bemould, the equipment were not complete, and many processing processes were collaborated with outsourcing. This mode of resource sharing for

injection mold manufacturers can also reduce the financial burden and management costs... But it can also cause many unfavorable factors, such as long delivery times (when encountering peak seasons, delivery times are far away),

lack of quality assurance, and an increase in overall molding.

After comprehensive consideration, we have gradually formed a complete team equipped with relevant equipment to support the independent completion of various

processing tasks. Bemould has its own mold workshop (processing workshop, assembly workshop), injection molding workshop, and independent testing room.

Welcome to email [email protected]

for anything about Plastic Injection Molding services .

Plastic Engineering

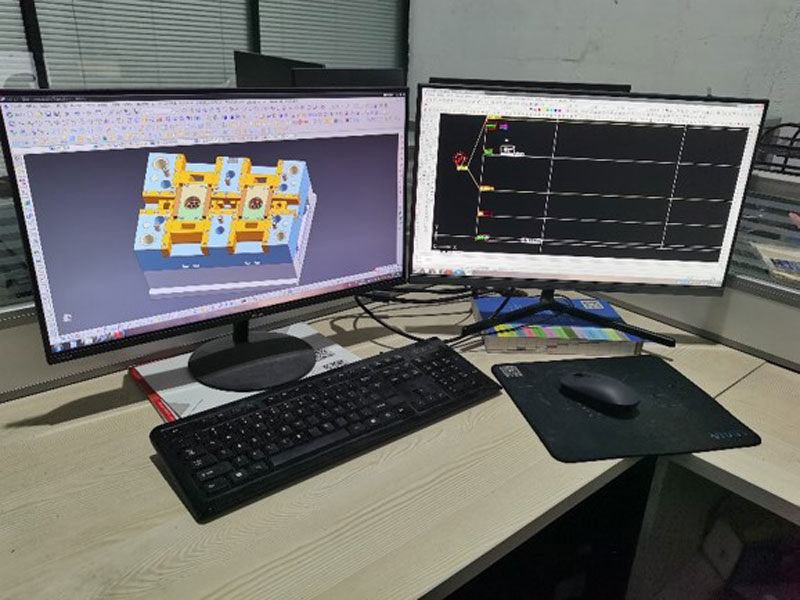

Injection Mold Design

Injection Mold Design & Tooling

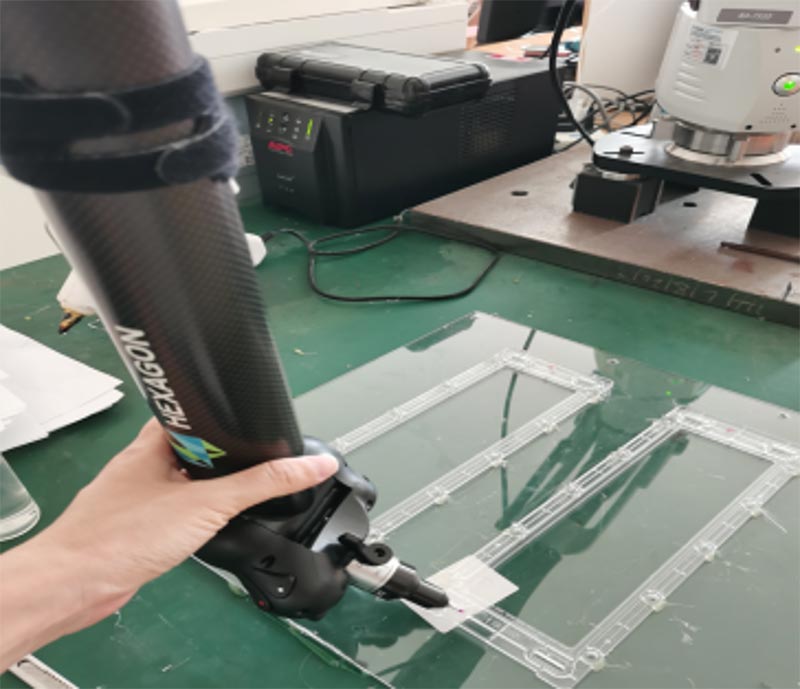

Quality Control

Plastic Injection Molding

Warehouse & Logistics

Our Expertise Engineers Will Serve You

Bemould'sprofessional injection molding engineers welcome all of you to inquire about injection molding related questions .

We firmly believe that a expertise team is the prerequisite for a company to serve its customers well. Only a professional team can bring us a professional knowledge base and skills. A professional team can save costs

for our company, bring high-quality products, and provide professional services, allowing our customers to cooperate with us more confidently .

The professional team of our Plastic Injection Molding includes R&D team,

injection mold design team, injection molding team, quality inspection team, and sales

team .

Our sales team is also professional, not only in terms of business collaboration.

Bemould requires sales to regularly participate in Plastic Injection Part & Mold Design training, and salespeople can promptly answer customers' common questions about plastic products without the need to transfer

to an engineer, saving customers' waiting time .

Welcome again to contact Bemould , our professional service ensures your peace of mind !

02

Excellent

Team

Members

04

Responsible

Sales Team

01

Professional

Designer

03

Experienced

Quality

Team

Frequently Asked Questions

-How do you know if injection molding is the suitable process for our products?

The product structure is complex, no matter through the design of slider, lifter, etc., the product can be demolded smoothly.

There will be no obvious injection molding defects in the early analysis of the

product, and it is common that the thickness of the product is too thick

-What kind of information is required for quoting a molding project?

We do want to evaluate the part using a 3D file and drawings output from any format, e.g. stp, .prt, .sldprt or others. If above information is not available , send us samples are also OK.

The resin that the

part will be molded from must be identified.

Estimated quantities over a set period of time, e.g. Annually , we can know how many cavities should be built.

-Do you provide PLASTIC INJECTION PARTS design services?

Bemould does not only do mold design , our professional team members also provide component part design services , We have third party partners that we can work with in conjunction with you, in order to design a part that meets your functional needs and has been optimized for resin, mold design, and moldability.

-Do you offer a service to evaluate my product for moldability or manufacturability when my part is in the design stage?

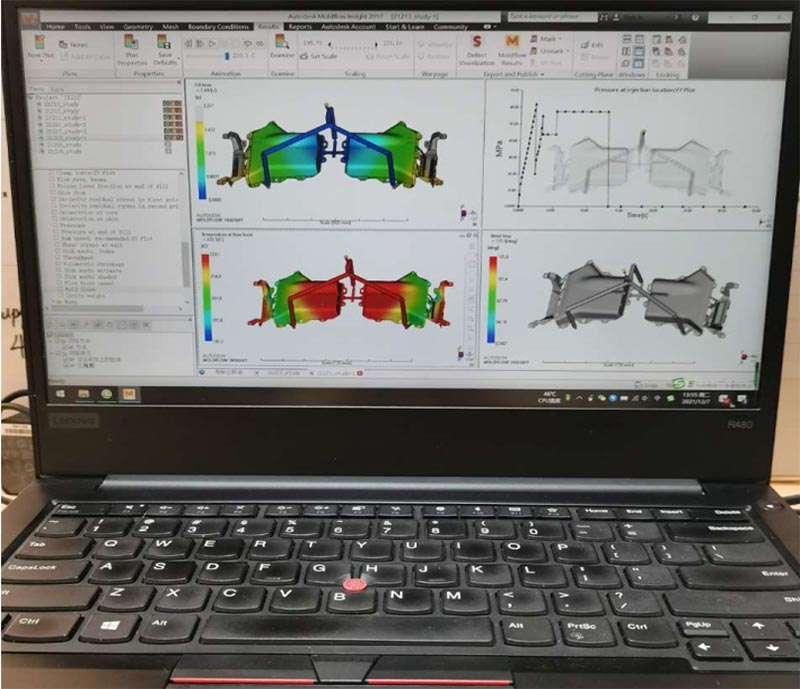

Yes we do. There’re two steps that we’ll do to know it , Pre-analysis -DFM and mold flow analysis

For existing customers, it is part of the service we provide for the new projects they are designing. we’ll provide DFM report and mold flow analysis report to tell them the results.

With new customers,

those services would be available on a project when released the PO.

-Do you design and make all of the new molds at Bemould?

Among Bemould's many mold development programs , 98% of moulds are designed and manufactured by Bemould. We believe that this will ensure the quality of the molds and at the same time provide our customers with the shortest lead time. In some cases, Bemould seeks to work with our equally specialized partners to help expedite the mold making process.

-How should I choose the right resin for my molded products?

It mainly depends on the end-use application of your product. We will be involved in discussing your part and its design requirements specification, and we can help you choose the right plastic or composite material.

-If we have exist mold and want to run production in Bemould , Do you accept molds from other sources?

Yes, Bemould does receive and run molds that were done at other suppliers, even overseas. Many Bemould customers have molds built in outside sources and sent molds to Bemould to start their production , we have a procedure in place for receiving , evaluationg and using molds from other suppliers.

-Do you offer extended molding services such as assembly, packaging, or decorating?

We have services option provided such as assembly work, CNC machining, 3D printing, and packaging.

-How do you ensure quality?

We have a complete set of testing procedures, and quality engineers run various tests in combination with the EPR+MES system, including incoming inspection, in-process inspection, warehousing inspection and a series of tests to ensure quality.

-Do you design and build molds?

Yes, we have our own design team and mold building team , we consider it an advantage that we both design and build our customers’ molds and then run the production . It makes for a much more smooth process in getting a mold up and running in production.

-Who owns the injection mold?

In all cases at Bemould the customer owns the mold. It is custom designed to make our customer’s parts . As such it is a customer asset that resides within our facility.

-How many shots will you guarantee for my mold?

Most mold life can last 20-500,000 times. According to the mold material and heat treatment method, it is common for the mold life to reach millions of times.

-How do you maintain my mold?

We will use your mold in production to make the parts that you require. Upon completion of each order we will inspect, clean and then preserve the mold so it can be shelved until you require more product.

-Can my mold be modified if I change my part designs?

It’s called design change , practically all molds can be modified to accommodate changes to your part design.

-Can you process insert molding mold?

Yes, insert molding is very often in our mold design . We have designs calling for just a few to as many as 20 inserts placed in the mold prior to the shot.

-Why should I entrust my project to you?

Bemould has 10 years of expertise in mold design, mold build, composite injection molding, and value add services. We only engage with customers and their projects that fit our type of program, we provide full services to simplify your supply chain and reduce time costs.

Didn’t find the answer you were looking for? Contact us today with your questions and a team member will get back to you as soon as possible.

Latest NewsMORE

-

5/21/2024

Dingzhou solutions to common injection molding industry pain points

In recent years, under the influence of many factors such as the upgrading of restricted plastic orders, repeated epidemics, rising raw materials and labor costs, the injection molding industry has ushered in many opportunities and challenges. The traditional injection molding industry generally has the characteristics of fast, batch and low profit, and the production mode is generally multi-variety and small-batch, which is a typical discrete industry. At present, China has become the worlds lar…

-

3/12/2024

5 Reasons to choose Ding Zhou to custom injection molding

Dingzhou Precision Injection Molding provides one-stop services, collaborates with you in all stages of product development, from rapid prototyping to production with our extensive knowledge and custom manufacturing, we support you in accelerating products to market .Here, I will share two injection molding cases to demonstrate the professional capabilities, rich experience, and high quality service of the Ding Zhou team to you.1.molded thread covers by plastic injection moldingMould design The m…

-

3/12/2024

See Ding Zhou injection molding How to control the mold fabricating cost

The current injection mold market is being affected by rising raw material prices and increased labor costs, resulting in a shrinking profit margin for injection molds. How to obtain orders in fierce market competition, ensure mold quality, and maximize mold profits as much as possible to achieve green manufacturing, Dingzhou Injection Molding is thinking about this issue every day. The cost control of injection mold manufacturing is imperative, and cost control lies in effective spending rather …

-

1/20/2024

Top 6 Plastic Injection Molding Manufacturers in China

Injection molds are important tools for manufacturing plastic products, widely used in various industries such as automotive manufacturing, electronic products, household appliances, industrial products, etc. As an important component of modern manufacturing, the mold industry has the characteristics of technology intensive, capital intensive, and labor-intensive. On a global scale, the mold industry has formed a good development momentum. From a regional perspective, Asia is the largest region i…