Custom injection molds case shares

OEM injection molding case 1 sharing

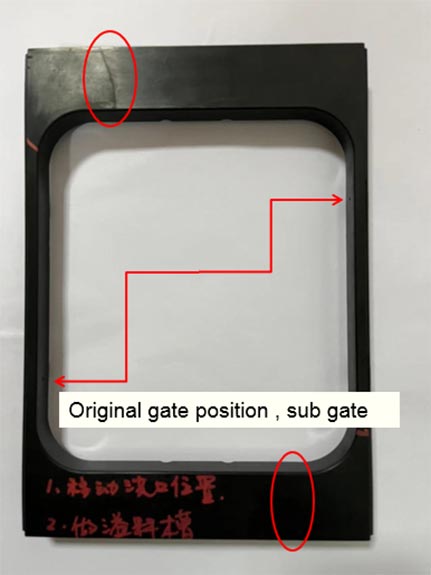

The injection molding defects : obvious weld lines at circled position, it’s appearance product , not allowed visible molding defects on part surface .

Root cause analysis :

Gate location design is not reasonable , it results in weld lines located in large surface .

The mold temperature is not enough ,there are obvious temperature difference .

Correction :

1. Adding overflow design at weld line location .

2. Moving gate location, let the weld line locate on narrow surface .

Take method 2 as the figure shown, let the weld line occurred on narrow surface .

✔:The molding defect get solved .

Custom-made injection molding solution case 2 sharing

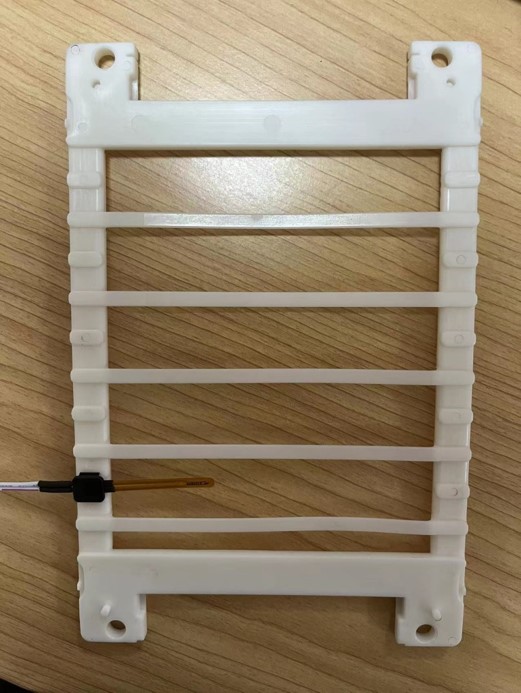

Custom-made injection molding components used in new energy industrial battery applications , According to the original data of the customer, the product and thermistor assembly are time-consuming and laborious, and they are not work well .

Our client hopes we can help optimize the design .

The engineers of Bemould added a buckle and a slot according to the actual use of the client . The feedback is good !

|

|