How to optimize the weld line on the surface of injection molded parts—New energy power equipment

Tuesday, 31 August 2021

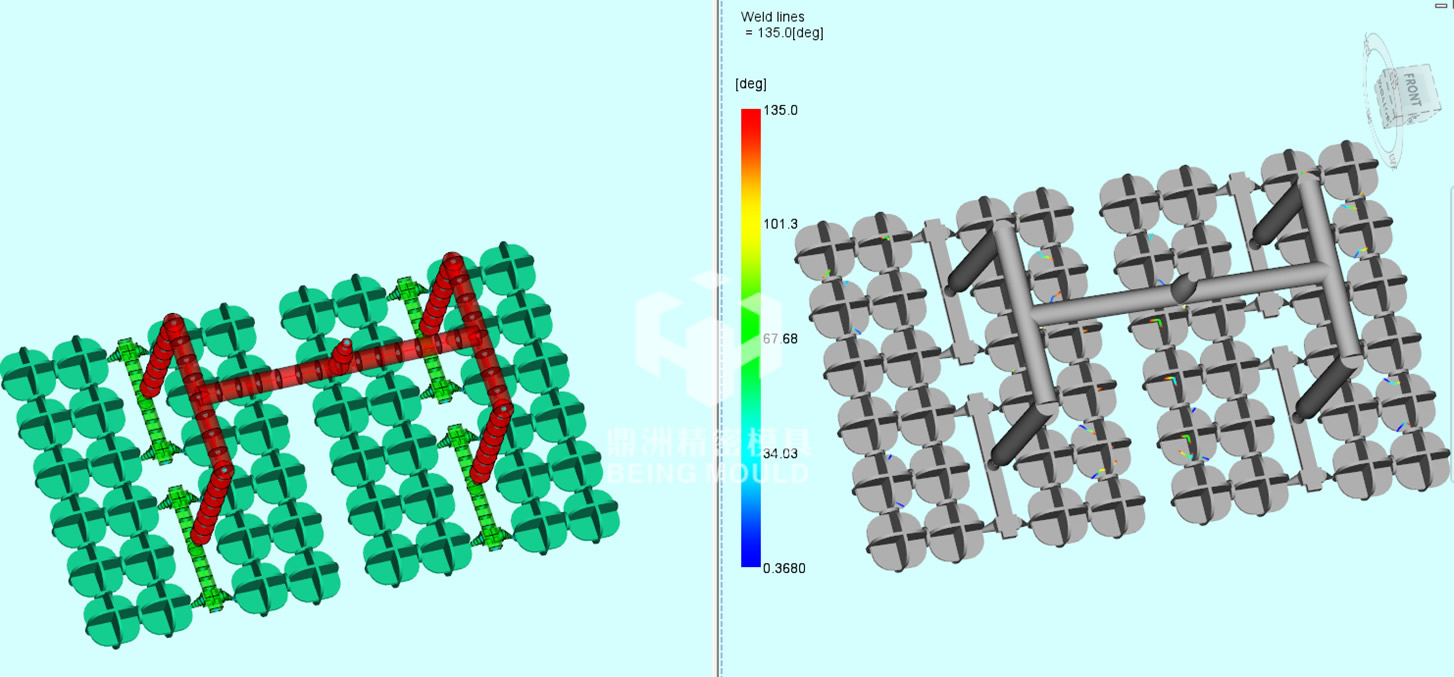

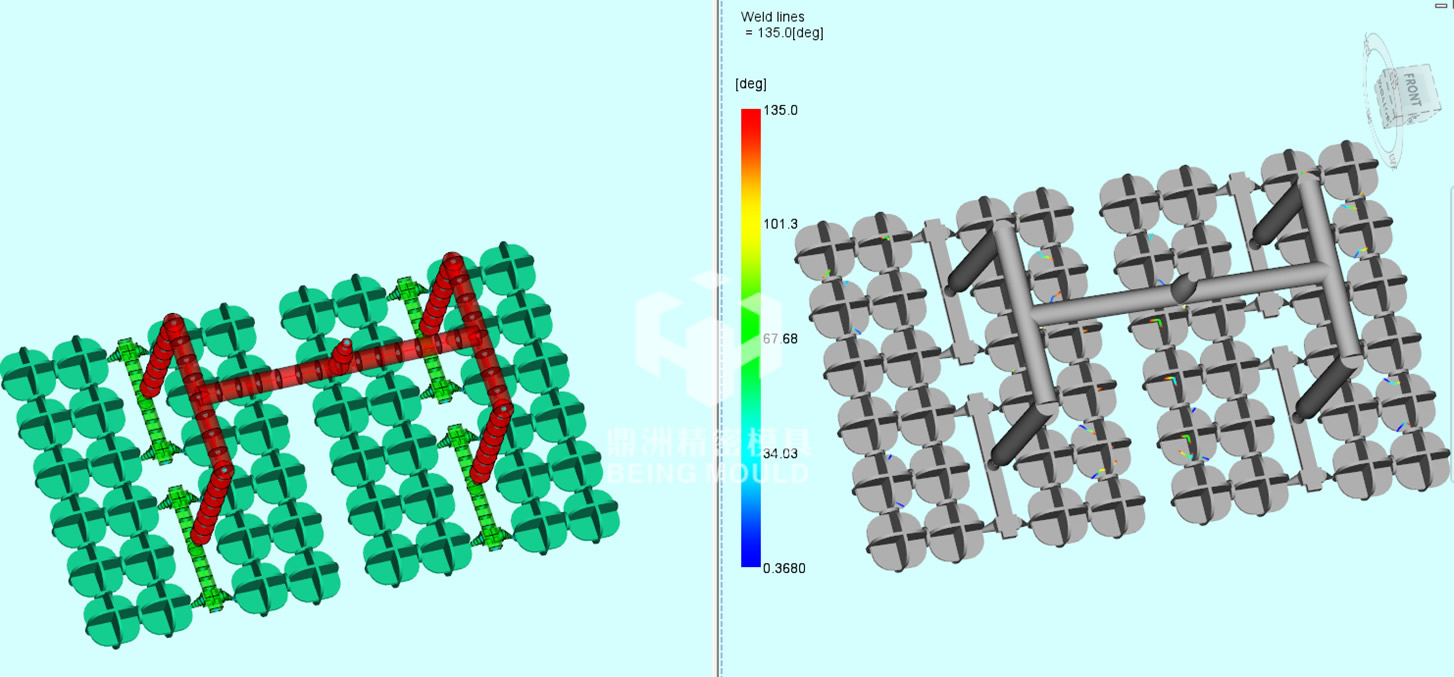

In injection molding, when the

plastic melt fills the mold cavity, if the temperature of the front melt of two

or more melts is not exactly the same when they meet, these melts cannot be

fully fused, and linear grooves are generated at the confluence to form fusion marks

.

The causes

and solutions of weld lines in injection molding are as follows:

1.The melt

temperature is too low ,Low temperature

melt has poor shunting and confluence performance and is easy to form weld

lines. When the inner and outer surfaces of plastic parts produce welding fine

lines at the same part, it is often due to poor welding caused by too low

material temperature. In this regard, the temperature of the barrel and nozzle

can be appropriately increased, or the injection cycle can be prolonged to

promote the rise of the material temperature. At the same time, the passing

amount of cooling water in the mold shall be controlled and the mold

temperature shall be appropriately increased. In general, the strength of the

plastic part at the melting mark is poor. If the corresponding part where the

welding mark occurs in the mold is locally heated and the local temperature of

the welding part of the formed part is increased, the strength of the plastic

part welding part can often be improved. If the low-temperature molding process

must be adopted due to special needs, the injection speed and injection

pressure can be appropriately increased to improve the confluence performance

of the melt, or a small amount of lubricant can be appropriately used in the

raw material formula to improve the flow performance of the melt.

2.The gate

position is unreasonable

, The gate

form with less diversion shall be adopted and the gate position shall be

reasonably selected to avoid inconsistent mold filling rate and interruption of

mold filling material flow as far as possible. Single point feeding shall be

selected when possible. In order to prevent low-temperature melt from injecting

into the mold cavity to produce fusion marks, a cold material cavity can be set

in the mold while increasing the mold temperature.

3.Poor mold exhaust

, At this

time, first check whether the mold exhaust hole is blocked by the solidified

product of the melt or other objects, and whether there is foreign matter at

the gate. If the carbonization point still appears after the blockage is

removed, an exhaust hole shall be added at the material collection point of the

die, or the material collection can be accelerated by repositioning the gate,

appropriately reducing the clamping force and increasing the exhaust gap. In

terms of injection molding process, auxiliary measures such as reducing

material temperature and mold temperature, shortening high-pressure injection

time and reducing injection pressure can be taken.

Share to:

Share to: