Mold flow analysis -case sharing

Mold flow analysis is a preliminary work of mold opening. It reduces the risk in product development, optimizes the product structure, shortens the product development cycle, succeeds in one mold test, saves energy and reduces consumption .

Here are two molding cases of mold flow analysis and one case not analyzed

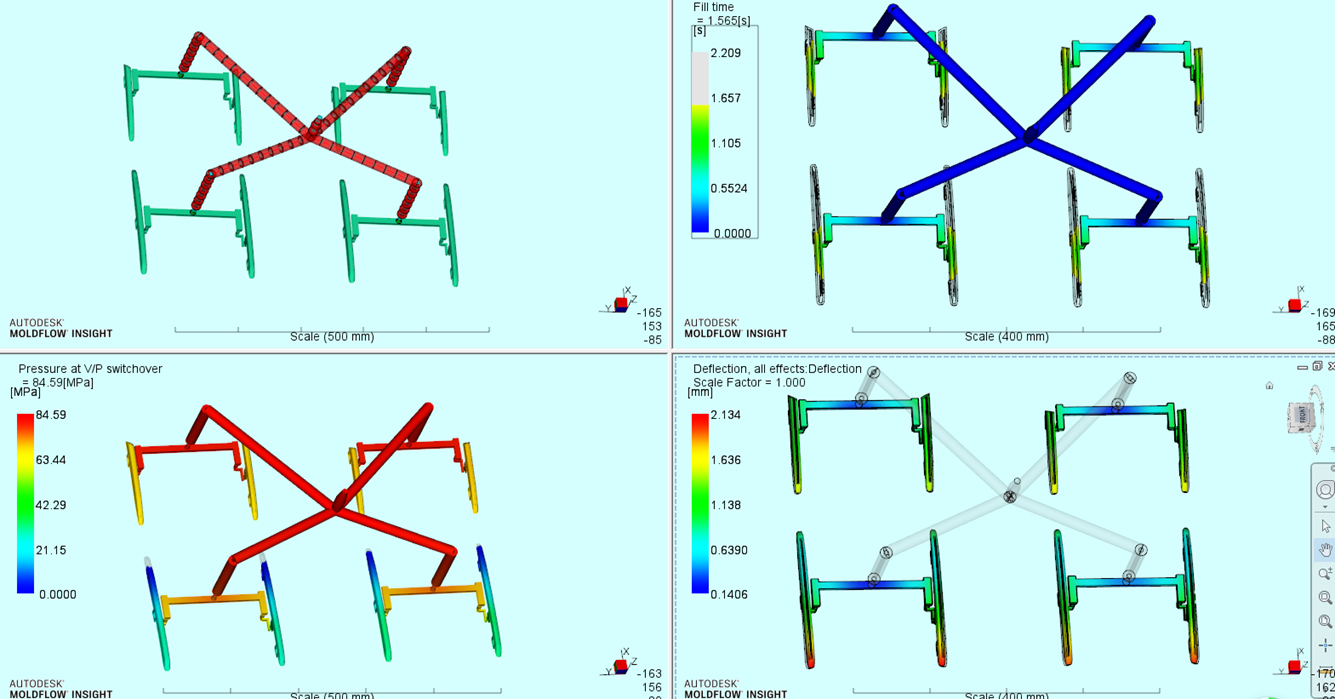

Case 1 Plastic Exterior Decoration Parts of Automobile

PC +ABS ,4 drops hot runner

The purpose of the analysis is to see the injection pressure and part deformation .

Through the analysis of the results, the rationality of the distribution of gate position and the product trend were judged .

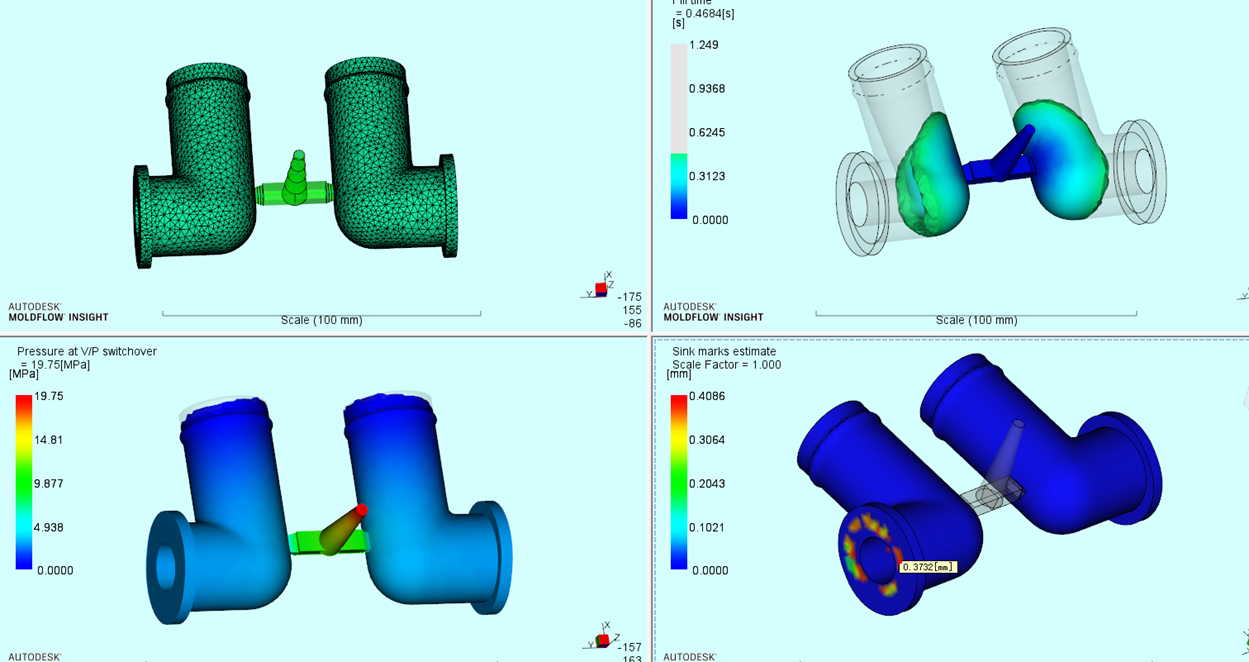

Case 2 Plastic fitting elbow

PVDF, cold runner , the wall thickness is up to 5.0mm .

The purpose of the analysis is to see the sink mark on part surface .

It can be judged from the analysis results that there will be obvious shrinkage marks on the product .

Case 3

No analysis , the edge of the gate is covered with burrs .

If run the analysis , I can judge whether the scheme is qualified through the following parameters , injection pressure ,clamp force , shrinkage …