Those things about injection mold trial

After the injection mold is processed and assembled, the master fitter will ask for a trial, and the main steps of the trial are as follows:

1.First,

check whether the materials are the same as the customer's requirements, then

clean the barrel, and check whether the temperature of the barrel and the mold

temperature are suitable.

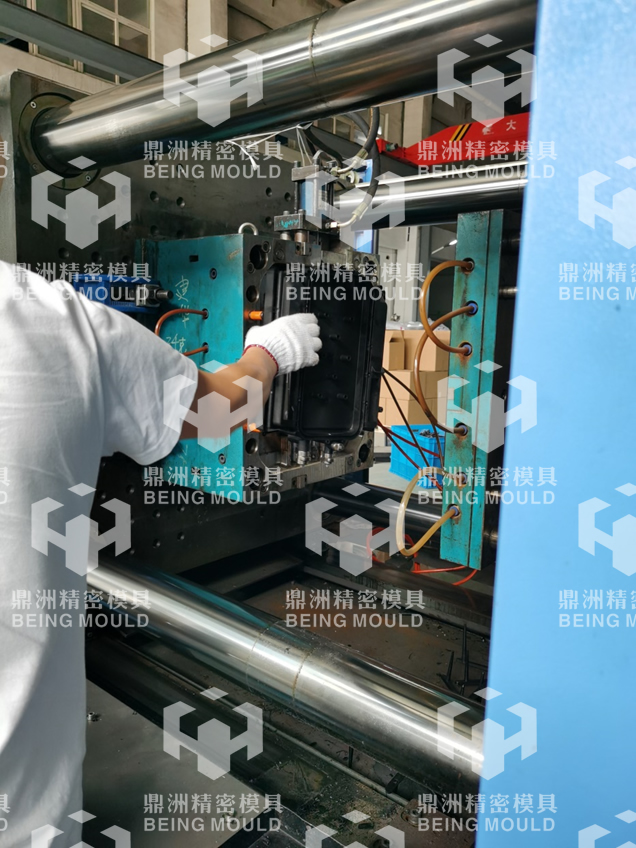

2.The mold

is installed on the machine, and the machine starts to heat up. At the

beginning, a few mold shortage products are shot, and then the process of

qualified products is gradually moved closer.

3.Trial molds,

one is the test mold, and the other is the molding

process.

After the qualified product is produced, the product is submitted to the

quality inspection to test the size and appearance of the product. The mold

will continue to produce products, test the stability of the mold and see if

the process can continue to be optimized, and make reasonable adjustments to

reduce the production cycle.

4.If you can’t get a visually qualified sample after debugging, find out the reason, the mold problem is also the early design problem... After finding the reason, rectify it, and continue to try the mold next time until the qualified parts can be produced.

Share to: